PCP Protheus x PPI-Multitask Integration

Business Context

- Manufacturing Execution Systems, or simply MES is the term used to refer to the systems focused on the management of production activities establishing a direct link between planning and shop floor. The MES systems generate precise information and in real time promoting the optimization of all production stages since the issue of an order to the shipment of finished products shipment.

The importance of these systems comes from the gap that regularly exist between the ERP (Enterprise Resource Planning) and the specific softwares of the production line. The MES can import data from ERP and integrate with the production daily routine, managing and synchronizing the productive tasks with the flow of materials.

Considering that in the supply chain the highest added value is in the production, it makes sense investing in systems optimizing the flow, control and quality of material (Source: PPI-Multitask). - Planning and Production Control Gathering of means of production (raw material, labor, and equipment) enables manufacture of products that arise from the action of productive systems. The plans are the guide of execution and in production control are commanded by the auxiliary body named Planning and Controlling of Production (PCP) that establishes the production line rules, aiming at an ordered and continuous flow of the productive process.

- Shop Floor Allows you to plan, punch and monitor activities executed in each work center of the plant and machine, enabling an integrated view of executed operations, under execution and to be processed. Allows the Management and Monitoring of results (productivity, efficiency, delays, quality, use, levels of downtime, scrap reason, deviation of real/standard time etc). In MES integrated use, punches are executed by MES system.

Systems Involved

- PCP PROTHEUS 11.80.14, 12.1.10 (Phase I)

- PCP - SIGASFC PROTHEUS 11.80.17 (Phase II)

- PC-FACTORY (PPI MULTITASK)

Integration

The aim of the PC Factory Integration (MES software of company PPI Multitask) X PROTHEUS is to make available to TOTVS customers a new option to control the production through the automation of processes, enabling the updating and extraction of online information to simplify the customers flow.

Scope

Enables the integration between the PCP module of SIGASFC Protheus with MES PC-Factory of PPI Multitask, aiming at controlling the annotation of production orders. Protheus is responsible by the creation of production orders and the PC-Factory with annotation.

The integration contemplates the following routines and processes in PHASE 1:

- Parameterization: Enables to parameterize the use of integration, indicating if it is ACTIVE. Indicates whether there is generation of XML files of information that is transferred between the systems, and also enables to define filters that are applied to information.

- Integrators: Adapters are functions responsible for sending or receiving information that is transferred between Protheus and PC Factory systems. Integration contemplates the following information: Product, stock location, resource, production orders, production annotation and stoppage annotation.

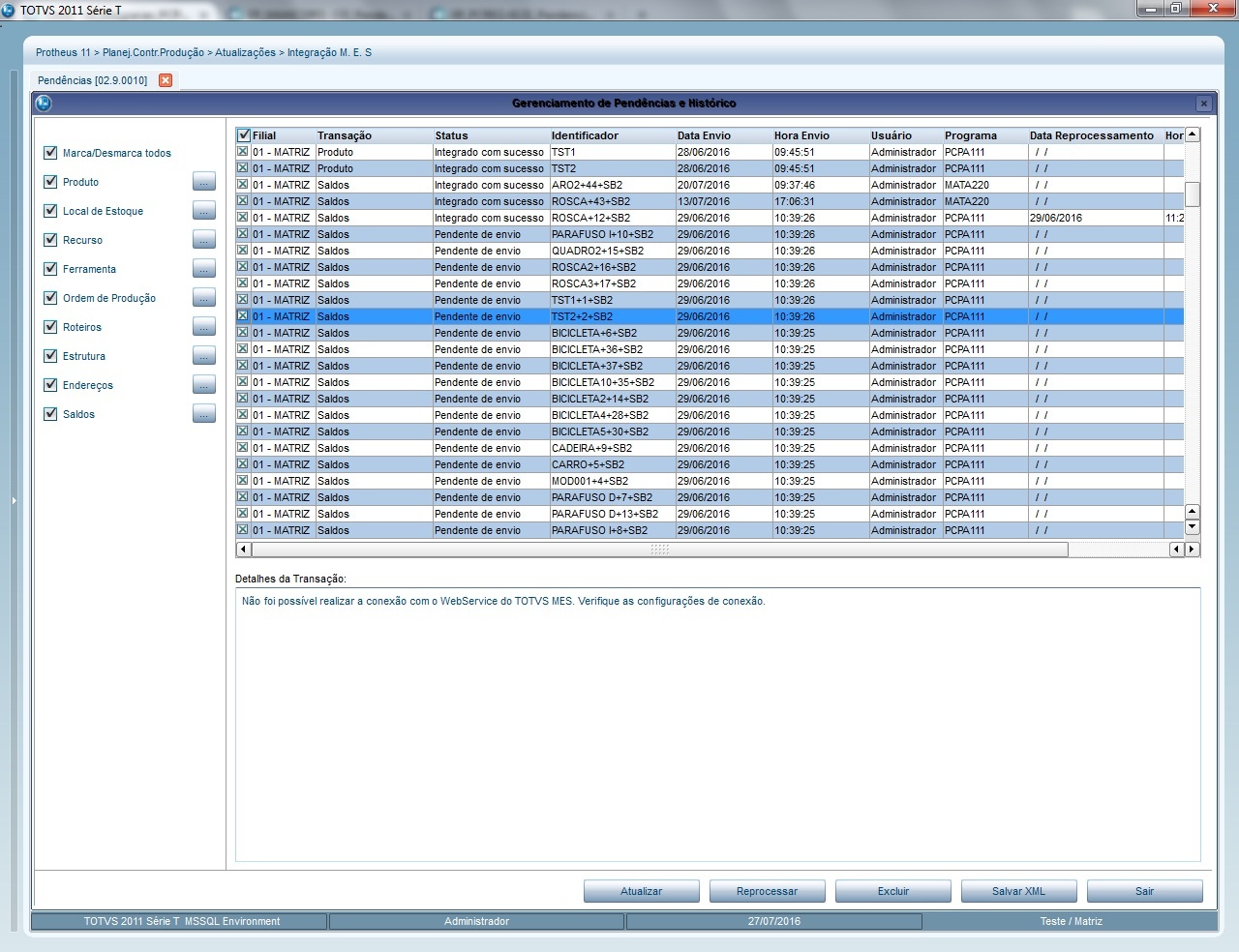

- Pendencies: Enables to manage the pendencies of PCP Protheus delivery to PC-Factory as well as to check the history and errors of integration process.

- WebService: Enables to process the annotation of production and stoppage sent from PC-Factory to Protheus;

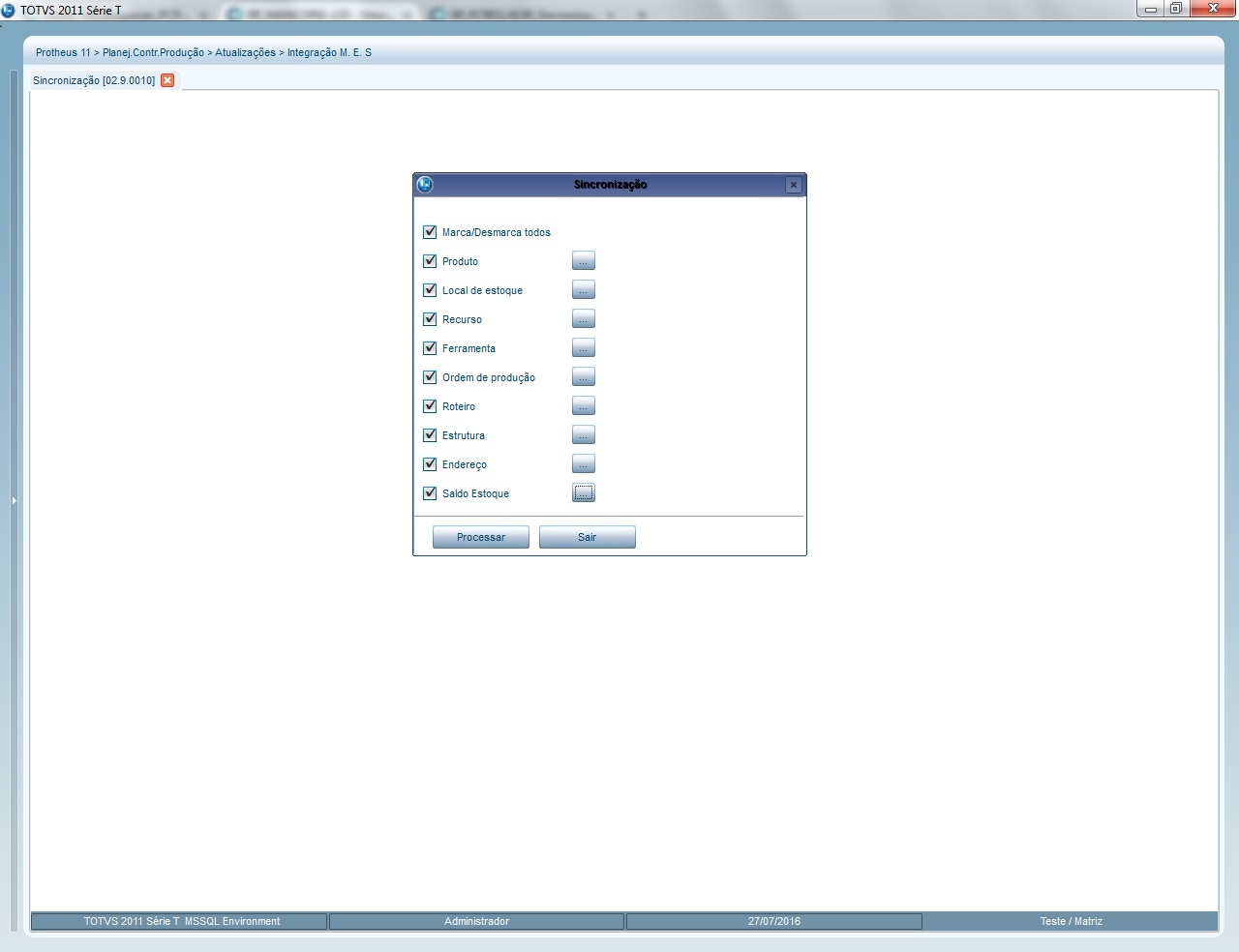

- Synchronization: Enables to execute the synchronization of data from PCP Protheus and PC-Factory. Able to send data from Products, Stock Location, Resource and Production Order.

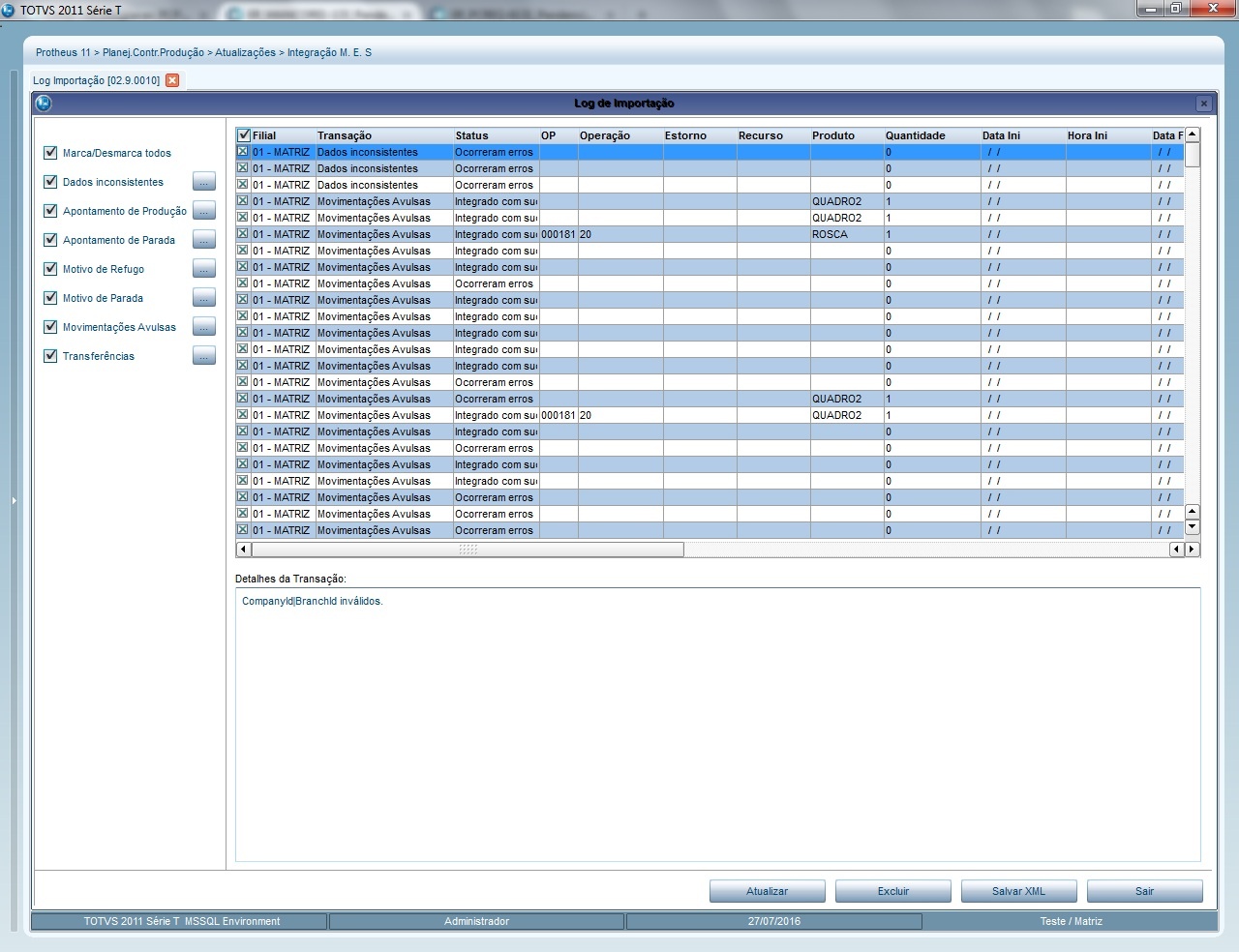

- Import Log: Enables to query the integration process of annotation of production and stoppage sent from PC-Factory to Protheus.

The integration contemplates the following routines and processes in PHASE 2:

Phase 2 contemplates the consumption of components, movements executed by PC-Factory and balances in stock. It also considers the SIGASFC - Shop Floor system.

- Parameterization: Enables to parameterize the use of integration, indicating if it is ACTIVE. Indicates whether there is generation of XML files of information that is transferred between the systems, and also enables to define filters that are applied to information.

- Integrators: Adapters are functions responsible for sending or receiving information that is transferred between Protheus and PC Factory systems. Integration contemplates the following information: Product, stock location, resource, machine, tools, script, structure, address, production order, balance in stock, movements and transfer of stock, annotation or production and stoppage annotation.

- Pendencies: Enables to manage the pendencies of PCP Protheus delivery to PC-Factory as well as to check the history and errors of integration process.

- WebService: Enables to process the annotation of production and stoppage sent from PC-Factory to Protheus;

- Synchronization: Enables to execute the synchronization of data from Protheus and PC-Factory. Able to send data from Products, Stock Location, Resource, Machine, Script, Structure, Address, Balance in Stock and Production Order.

- Import Log: Enables to query the integration process of annotation of production, refusal and stoppage sent from PC-Factory to Protheus.

Note:

Integration does not contemplate the generation of orders by APS.

Install/Implement/Use Requirements

For Protheus version 12, apply package of updates from version 12.1.10 in Phase I. It can also be used in version 11.80.14 for Phase I and 11.80.17 for Phase II. Run the update of dictionary with program U_UPDPCP34.

Build must be equal to or later than 7.00.131227A and date 9/8/2014.

IP Address and released port for WebService execution. These data are used in APPSERVER.INI file in session WEBSERVICE.

Update APPSERVER.INI file in session WEBSERVICE.

To configure a WebService, check this configuration: http://tdn.totvs.com/pages/viewpage.action?pageId=6064937

Exemplo :

; WEBSERVICE CONFIGURATION

[WebServices]

Enable=1

Environment=mssqlserver

Conout=1

Trace=1

PrepareIn=99,01

NameSpace=http://10.80.62.219:8090

URLLocation=http://10.80.62.219

[HTTP]

enable=1

port=8090

[ONSTART]

JOBS=JOB_WS_9901

[10.80.62.219]

ENABLE=1

Trace=1

PATH=C:\TOTVS 11\Microsiga\Protheus_Data\web\ws

ENVIRONMENT=mssqlserver

INSTANCENAME=WS

RESPONSEJOB=JOB_WS_9901

DEFAULTPAGE=wsindex.apw

[JOB_WS_9901]

TYPE=WEBEX

ENVIRONMENT=mssqlserver

INSTANCES=1,20

SIGAWEB=WS

INSTANCENAME=WS

ONSTART=__WSSTART

ONCONNECT=__WSCONNECT

;FIM CONFIGURACAO WEBSERVICE

You can also update in APPSERVER.INI file in session PROXY (if there is configured proxy)

[PROXY]

Enable=1

Server=proxy-jv.jv01.local

Port=8080

User=XXXXX

Password=*******

Installation/Updating

The PCP Protheus x PC-Factory PPI-Multitask is activated through the following steps:

- Open the progrm of Integration Parameters: PCPA109 (Updates -> Integration MES-> Parameters).

- Set the field Active to "1- Active".

- In the field path enter the URL of WebService of PPI-Multitask.

- Check WebService connectivity through Test button.

- Indicate whether the integration physically generate the XML files.

- Configure the filters for each information that is transferred between the systems.

- Confirm the activation through the button CONFIRM.

The Test button check whether you can execute the connection with WebService entered in the field Path. This button has two returns:

- Connection with WebService successfully executed.

- Unable to execute the connection with WebService of PCFactory.

Selecting the field Generate XML, the XML of the exchanged messages is generated. If you do not select it, the system saves it only in tables. You are not required to create files. It works as a useful tool to find problems and it can be saved in XML directory successfully sent or pending XMLs.

The file names follow these standard:

OK_<MSG>_<DATAHORA>_<REGISTRO>

PEND_<MSG>_<DATAHORA>_<REGISTRO>

ERR_<MSG>_<DATAHORA>_<REGISTRO>

Where: OK - Message sent with no problems

PEND- Message not sent

ERR - Message sent, but returned with error.

MSG - Name of message. Ex.: Item, Wharehouse, Workcenter, etc.

DATETIME: Date and Time of sending

RECORD: Record code being sent. Ex.: Item code, order number, etc.

For each file moved (product, stock location, resource, tool, machine, script, structure, address, movements, balances and production order) a folder exists. For each folder, you can assemble filters and define parameterizations. These filters are used in routines that send PC-Factory information enabling you to select what must be sent. The fields of selected table (folders) and operators are displayed so filters are assembled. If there is no filter registered, every record added, edited or deleted is sent to PC-Factory. To assemble the filters, the user must know the database, as table names and fields are directly used.

Example:

To assemble a filter, so only products classified as Finished Product are sent. Filter is: B1_TIPO = "PA"

The delivery of Protheus information for PC-Factory PPI Multitask, the following transactions occur:

- Register, change and deletion of product MATA010, AGRA045 stock location and MATA610, SFCA006 and SFCA002 resource;

- Register and change of orders MATA650;

- Process to FIRM orders MATA651;

- Maintenance of operations MATA632;

- Maintenance of allocation, MATA380 and MATA381;

- Register, change and deletion of Operations x Components MATA637;

- Machine Load MATA690;

- Calculation of MRP MATA712 (version 11.8) or PCPA107 (version 12);

- Register, change and deletion of structure, MATA200;

- Production splits generated by routines that handle order, and SFC310 annotation model 1 of shop floor.

- Register, change and deletion of address MATA015;

- Register, change and deletion of tools MATA015;

- Balance Update

- Inbound Invoice - Routines executing function B2ATUCOMD1;

- Sales Invoice - Routines executing function B2ATUCOMD2;

- Internal Movement - Routines executing function B2ATUCOMD3;

- Addition of balance MATA220 and MATA805.

The delivery of PCP-Factory PPI Multitask information for Protheus, the following transactions occur:

- Register of stoppage reasons SFCA004;

- Register of scrap reasons SFCA003;

- Stock Separate movements. Inbound MATA250. Outbound MATA240;

- Transfer of stock MATA261;

- Annotation of production MATA681 and SFCA310;

- Annotation of stoppage MATA682 and SFCA311;

- Refusal, annotation of loss, MATA685.

Version Control

TOTVS group, represented by its brands, manages the layout progress demands and other adjustments, agreeing together with requesters the release approval term.

All progress scheduled must be discussed and approved by brands before the start of development and is only developed in case of agreement of brands and alignment with directive defined by TOTVS Integration Committee.

Support

All lines are responsible for support to integration resources; hence, the support teams of RM Connector and Protheus® Back Office products are ready to make the first analysis and, whenever needed, to transfer it to the fittest team in each case.

Note:

This support model is being reviewed by TOTVS.

Transactions/Entities/Singles Messages

The following transactions are exchanged between TOTVS and PPI-Multitask:

Method | ID | Description | Origin | Destination | XSD (versions may vary) | Programs | Table |

Registers | 01 | Product | Protheus | PC-Factory | Item_3_001.xsd | MATA010 | SB1 |

02 | Stock Location | Protheus | PC-Factory | Warehouse_1_001.xsd | AGRA045 | NNR | |

03 | Machines | Protheus | PC-Factory | Machine_1_000.xsd | MATA610 SFCA002 | SH1 CYB | |

| 04 | Resources | Protheus | PC-Factory | Resource_1_000 | MATA620 SFCA006 | SH4 CYH | |

| 05 | Structure | Protheus | PC-Factory | ItemStructure_1_000 | MATA200 | SG1 | |

| 06 | Script | Protheus | PC-Factory | ItemScript_1_000 | MATA632 MATA637 | SG2 | |

07 | Production Order | Protheus | PC-Factory | ProductionOrder_2_004.xsd | MATA650 MATA651 MATA380 MATA381 MATA690 MATA712 PCPA107 SFCA310 | SC2 | |

| 08 | Address | Protheus | PC-Factory | AddressStock_1_000 | MATA015 | SBE | |

| 09 | Stock | Protheus | PC-Factory | ItemStockLevel_1_000 | B2ATUCOMD1 B2ATUCOMD2 B2ATUCOMD3 MATA220 MATA805 | SB2 SB8 SBF | |

Processes | 09 | Reason of Stoppage | PC-Factory | Protheus | StopReason_1_000 | CFGX016 SFCA004 | SX5 CYN |

| 10 | Reason of Scrap | PC-Factory | Protheus | WasteReason_1_000 | CFGX016 SFCA003 | SX5 CYO | |

| 11 | Annotation of Production | PC-Factory | Protheus | ProductionAppointment_2_000 | MATA681 SFCA316 | SH6 SD3 CYV | |

12 | Annotation of Stoppage | PC-Factory | Protheus | StopReport_1_001 | MATA682 SFCA311 | SH6 CYX | |

| 13 | Stock - Request | PC-Factory | Protheus | StockLevel_2_00 | SB2 SB8 SBF | ||

| 14 | Movements | PC-Factory | Protheus | MovementsInternal_1_001 | MATA240 MATA250 | SD3 | |

| 15 | Transfer | PC-Factory | Protheus | TransferWarehouse_1_003 | MATA261 | SD3 | |

| 16 | Refusal | PC-Factory | Protheus | Refusal_1_000 | MATA685 | SBC |

Information Flow

Transactions information flow:

- Product, stock location and resource: during creation, change and deletionof a product in program MATA010, from a stock location in program AGRA045 or of a resource in programs MATA610 or SFCA006 or SFCA002 (machine) and tools in MATA620. The programs check whether the integration is active, and if positive, they deliver the register to PC-Factory. If there is no error, the register does not display any message, if there is an error, a message is displayed questioning whether to create a delivery pendency in program PCPA110. If you choose to operate a pendency, the process is committed in Protheus, and the updating for PC-Factory must be executed through PCPA110.

In the engineering, the register of structure MATA200 and script MATA632 or MATA637 and addresses MATA015 are integrated whenever a record is created, changed or deleted. - Production order: during creation and change of a production order, or during the change of the status of an order (allocation/machine load, request, operations change or pledge, MRP creation of splits), the program checks whether the integration is active and, if it is active, it executes the delivery of registration for PC-Factory. If there is no error, the register does not display any message. In case of error, a message is displayed and a delivery pendency can be created in program PCPA110. At the end of the process, the routines processing multiple orders, for example machine load, the amount of records that were sent to PPI-Multitask is displayed and the ones which had delivery pendency. Note: Some routines generate pendencies without executing the questioning due to the number of processed orders.

Routines affected by integration: Maintenance of Orders (MATA650), Routine to Establish Orders (MATA651), Maintenance of Operations (MATA632 or MATA637), Maintenance of Allocation (MATA380 and MATA381), Machine Load (MATA690) amd MRP (MATA712), Production splits (SFCA310). - Program of PCPA110 pendencies management - this program aims at managing pendencies/exceptions related to integration that are created when the message was not sent to PC-Factory, whether they are pendencies or errors. Enables the reprocessing of a message, deletion of a pendency and the XML view, besides having the filter per date of delivery, transaction, type of pendency and generating routine. The routine also enables to query the messages successfully sent.

- Synchronization program PCPA111 - enables the deliver of information from product, stock location, resource, tools, script, structure, address, balance in stock and production order, it aims at updating the PC Factory database. Besides filters defined in PCPA109, you can also add new filters for each table.

- Production Annotation: This routine consists in WebService to receive annotation of production executed by PC-Factory. You can also process production annotation and resource stoppage. Executes the same process the routines MATA681 and MATA682. When the Shop Floor is installed, it runs the same process the routine SFCA316 and SFCA311.

The integration flow is the following: a. the Operator normally reports according to its operation in PCFactory b. In a batch or triggered process, parallel to the system, the message is assembled (XML) according to Schema of Single Message TOTVS and the delivery of message (XML) for Protheus, validating the message and follow the respective business adapter up (MATA681/MATA682 or SFCA316/SFCA311) for processing. c. In case of mistakes, this report has pending status for delivery in the MES software and the user take actions in PC-FActory (Protheus does not keep traceability of receipt messages, but it registeres in LOG the processing). d. In case of success in report, the number of the report record executed in Protheus returns to PC-Factory. This number can be used in case of reversal. - UPdate of balance in PC-Factory will happen as follows:

a. Request: the PC-Factory requests balance generating request XML message. In this message, you can request balance per item, per stock location, among others.

b. Protheus Updating: When balance is updated, Protheus must send a XML message to PC-Factory. The main routines of ERP as inbound and sales inbound, some internal movements and addition of balance through MATA220 and MATA805 are considered. - Stock movements: When PC-Factory performs stock movements and transfers, these movements are updated in Protheus.

In case of movements, if I (input), it must run MATA250. If O (output), it must run MATA240. In case of transfers, it runs MATA261. - Refusal/annotation of loss. This routine consists in WebService to receive the refusal records in PC-Factory. The same process is executed in MATA685 routines.

- Query of Import Log PCPA112: This routine consists in the query of annotation records that were processed by the integration Protheus x PC-Factory. Routine must display the annotation executed and the status of each process.

Entry Point

To make the use of integration easier and flexible in any productive environment, some entry points were created to solve possible specific situations not answered by the default process and also to enable more precise configurations in the integration use:

Annotation: The entry point MATI681CRG enables to add information that is used in annotation of production and in the stoppage annotation, table SH6. Example: In case there is a specific field or table not handled by the integration, you can use this function to set its content. Details in: MATI681CRG_Add_information_Adapter_of_annotation.

Annotation: The entry point MT680VAL enables to validate if any information must be mandatory as time, quantity, among others. These validations are under the customers' responsibility, as each has its own rule. Details in: MT680VAL - Addition of Productions.

Annotation: The entry point MATI680OPR enables to change the code of operation received in the annotation of production. Details in: MATI681OPR_Edit_operation_code_message_annotation_production.

Annotation: The entry point MTI681QTAP enables to edit the quantity received in the annotation of production. This entry point is indicated to apply the conversion factor in the amount of annotation when ERP and PC-Factory work with different unit of measurement. Details in: MTI681QTAP_Edit_amount_of_annotation_ProductionAppointment.

Annotation: The entry point MATI681EXC enables to check whether the annotation is executed. This entry point is indicated for validations that hinder the annotation of production and stoppage. It is also used for cases in which you have to update some information before annotation (example: reversal an address). Details in: MATI681EXC_Processes_Message_Annotation.

Production Order: The Entry Point MTI650ADOP enables to add a new operation in the production orders message. For each operation being sent this entry point is executed once. Details in:: MTI650ADOP_Add new operation of production order adapter.

Production Order: Production Order: The Entry Point MTI650FCOP enables to change the second unit of measure of the operation being sent in the production orders message. Details in:: MTI650FCOP_Change_conversion_factor_second_unit_of_operation_measure_adapter_production_order.

Production Order: The Entry Point MTI650QTOP enables to change the amount of operation being sent in the production orders message. Details in: MTI650QTOP_Change_quantity_of_operation_adapter_production_order.

Production Order: The Entry Point MTI650UMOP enables to change the second unit of measure of the operation being sent in the production orders message. Details in: MTI650UMOP_Change_second_unit_of_measure_of_operation_adapter_productionn_order.

Production Order: The Entry Point MTI650TMAC enables to change the machine time (TimeMachine) in the message of ProductionOrder. Details in: MTI650TMAC_Edit_amount_of_machine_time_production_order.

Production Order: The Entry Point MTI650LOTE enables to generate the Batch of the order in the tag LotCode in the message ProductionOrder. Details in: MTI650LOTE_Add_batch_in_message_of_production_orders

Registers: The Entry Point PCPXFUNPPI enables to inhibit the integration in certain routine. Example: If you do not want integration to occur in the creation of MATA650 orders, you can use this function to inhibit the use. Details in: PCPXFUNPPI_Routines_not_executing_integration_with_the_PC_Factory.

Register of Item: The Entry Point PCPADDTAGS enables to add specific tags in TOTVS standard messages. It is enabled for the registration of the item MATA010. Details in: PCPADDTAGS_Add_information_XML_integration_TOTVS_MES.

Register of Processes: The Entry Point PCPADDTAGS enables to add specific tags in TOTVS standar messages. It is enabled for the registration of script MATA632. Details in: PCPADDTAGS_Add_information_XML_integration_TOTVS_MES

Internal Movements. The entry points MATI250CRG and MATI240CRG enable specific validation. These validations are under the customers' responsibility, as each has its own rule. You cannot generate the values of fields that were generated by message. Details in:MATI240CRG_Add_information_Adapter_of_internal_movements and MATI250CRG_Add_information_Adapter_of_production_movements

Transfers: The entry point MI261RCV does not enable the execution of the integration. Details in: MI261RCV_Execute_integration_TransferWarehouse

Refusal: The Entry Point MATI685EXC enables to check whether the refusal is executed. This entry point is indicated for the validations hindering the annotation of refusal or updating of information necessary to execute the refusal. Details in: MATI685EXC_Processes_Message_Refusal

Execute in various branches

In an environment with various branches, just one WEBSERVICE is necessary for execution. The TAGs indicate the branch in which the annotation is processes:

<CompanyId>10</CompanyId>

<BranchId>CLSC0001</BranchId>

Note: When these tags are in blank the system considers what is defined in APPSERVER.ini in session WEBSERVICE field PrepareIn.

[WebServices]

PrepareIn=99,01

Control of latency

There are situations in which the webservice waiting time is lower than the time of processing of information to ERP. There may be situations in which the ERP continues to process the import and the WebService of PC-Factory stops waiting for the answer. When PC-Factory does not receive the answer in time, the same file is resent, generating then duplicity in the message processing.

Solution:

Control ID of PC-Factory for received messages. Every received message must be handled like this:

- ProductionAppointment

- StopReport

- MovementsInternal

- TransferWarehouse

- StopReason

- WasteReason

In the XML´s, the TAG Key name = "IDPCfactory" is used.

<BusinessEvent>

<Entity>Entity</Entity>

<Event>upsert</Event>

<Identification>

<key name="IDPCFactory">29892829</key>

</Identification>

</BusinessEvent>

The return with error displays a message with the following pattern:

<ProcessedOn>2017-03-28T09:11:17</ProcessedOn>

<Status>ERROR</Status>

<ListOfMessages>

<Message type="ERROR" code="N">MENSAGEM</Message>

</ListOfMessages>

</ProcessingInformation>

The return XML must follow this rule:

- When ID is processed and has ERROR

Retorns the ID PC-Factory in tag <UUID>

In the tag Message type="ERROR" code="2", uses the 2 to indicate error.

The message is: ID xxxx already processed. Status: error message”.

Example: <Message type="ERROR" code="2">ID productionappointment-0038 already processed. Status: ProductionOrderNumber not registered in Protheus.</Message>

- When ID is already successfully processed

Retorns the ID PC-Factory in the tag <UUID>

In the tag Message type="ERROR" code="3", uses the 3 to indicate the successfull processing.

The message is: "ID xxxx already processed. Status: ID of Protheus" or "ID xxxx already processed. Status: Reprocessed. ID of Protheus" when PC-Factory sends more than once.

Example 1: <Message type="ERROR" code="3">ID productionappointment-0038 already processed. Status: 5091</Message>

Example 2: <Message type="ERROR" code="3">ID productionappointment-0038 already processed. Status: Reprocessed. 5091</Message>.

- When ID already is in base but in processing

Retorns the ID PC-Factory in the tag <UUID>

In the tag Message type="ERROR" code="4", uses the 4 to indicate that is in processing.

The message is: ID xxxx is being processed by Protheus.

Example: <Message type="ERROR" code="4">ID apapapapeaaa is being processed by Protheus.</Message>

Note:

The return, when message is processed "right away" , within the waiting time of the webservice, is "1" - Processed for the first time with ERROR or OK.

Example:

With Error:

<ProcessingInformation>

<ProcessedOn>2017-03-28T09:00:03</ProcessedOn>

<Status>ERROR</Status>

<ListOfMessages>

<Message type="ERROR" code="1">ProductionOrderNumber not registered in protheus.</Message>

</ListOfMessages>

</ProcessingInformation>

Successfully:

<ProcessingInformation>

<ProcessedOn>2017-03-28T08:57:28</ProcessedOn>

<Status>OK</Status>

</ProcessingInformation>

<ReturnContent>

<ListOfInternalId>

<InternalId>

<Name>PRODUCTIONAPPOINTMENTINTERNALID</Name>

<Destination>5090</Destination>

</InternalId>

</ListOfInternalId>

</ReturnContent>

Unexpected situations may occur: the stoppage of Protheus service, downsizing of database, power outage, among others. If during the integration processing, the record of PC-Factory (ID of PC-Factory) may be locked up and there is no output of message from the processing queue. To handle this situation:

The PC-Factory tries to send by determination of time - time which is parameterized in PC-Factory. If you continue to receive the same message after the parameterized time, PC-Factory generates pendency of delivery and moves to the next record. Upon doing this, a counter of messages that were not sent is generated. When this counter reaches a (parameterized) limit, the integration process is stopped so the users can solve the problem. The processing control is registered in LOG SOH table.

Check below, table of sent codes:

Code | Message | Table of control - SOH.OH_STATUS |

1 | Processed in the first attempt with ERROR or OK | 1 or 2 |

2 | Record already processed with error return | 2 |

3 | Record already processed with success | 1 |

4 | Record being processed | 0 |

Important:

- If a record gets locked with status "record being processed", it can be unlocked by routine PCPA112, including the corresponding IDMES.

- The reprocessing of a message with ERROR(2) can be done passing the tag Reprocess = true.

Example:

<BusinessEvent>

<Entity>productionappointment</Entity>

<Event>upsert</Event>

<Identification>

<key name="IDPCFactory">9o93049u88557</key>

<key name="Reprocess">true</key>

</Identification>

</BusinessEvent>

Routines

Parameterization - PCPA109

Setting parameters directly influences records not moved between the two systems.

The parameter settings routine has the following fields:

- Active: It indicates whether the integration is active. When you select this field, the others are disabled. If this field is not marked, you cannot perform any other action in the routine.

- Path: It indicates the path of the PC-Factory WebService. After the path, there is a test button to check if the webservice is active.

- It has a XML panel.

This panel indicates:

- Generate XML - By selecting this field, it generates the XML of exchanged messages, If you do not select it, the system saves it only in tables. You are not required to create files. Use it as a tool to find problems. The content sent is always based on what is registered in the table.

- Sent - Directory where XMLs sent to PC-Factory are saved

- Pending - Directory where XMLs not sent PC-Factory are saved

The name of the files follows the standard below:

OK_<MSG>_<DATAHORA>_<REGISTRO>

PEND_<MSG>_<DATAHORA>_<REGISTRO>

ERR_<MSG>_<DATAHORA>_<REGISTRO>

Where: OK - Message sent with no problems

PEND- Message not sent

ERR - Message sent, but returned with error.

MSG - Name of message. Ex.: Item, Wharehouse, Workcenter, etc.

DATETIME: Date and Time of sending

RECORD: Record code being sent. Ex.: Item code, order number, etc.

Note: If you select Generate XML, you must enter the directories.

Each file transacted has a folder. For each folder, you can assemble filters. These filters are used in routines that send PC-Factory information enabling you to select what must be sent. The fields of selected table (folders) and operators are displayed so filters are assembled. Like the filters, some files are parameterized.

The routine has the following folders:

- Product

- Stock Location

- Resource

- Machine

The machine folder is only displayed when shop floor is in use. - Tool

- Production Order

MRP Panel: Indicates how the system must behave in relation to the orders generated by MRP. It will have the following options:

"Does not integrate": The orders generated by MRP are not sent to PC-Factory by the MRP calculation.

"Generate Pendency": The orders generated by MRP are registered in the pendencies of delivery

"Integrates": The orders generated by MRP are sent to PC-Factory by the MRP calculation.

For production order folder, a field to determine how the consumption of components in the panel "Consumption of Components". This field may have the following values:

"1" - BackFlush: Whenever issue of components is executed according to what is defined in Engineering.

"2" - Actual Consumption: Consumption according to component list.Painel "Operações": Define se o filtro criado no folder "Roteiros" deve ser utilizado para filtrar as operações da ordem de produção.

"Scrap" Panel: Defines the location of stock/deposit for the scrapped item when scrap is the same product of the production order. When the deposit - "WharehouseCodeTo" is in blank, in the message ProductionAppointment, use what was defined in the parameter.

- Scripts

- Structure

- Address

- Movimentos e transferência

Os movimentos de estoque, entrada ou saída e também as transferências são arquivos recebidos pelo Protheus. Não necessita de filtros, porém deverão ser criados alguns parâmetros para o processamento. São eles:

Type of Input Movement: Use field SOE.OE_VAR1

Type of Output Movement: Use field SOE.OE_VAR2

These types of movements are registered in MATA230 - Stock balance

For Stock balance folder, the option has three filters. Table SB2, SB8 and SBF.

It can also indicate in which process of movement, balance is sent to PC-Factory

Where:

Inbound Invoice: SOE.OE_VAR1 (Marked = 1; Unmarked = 0 )

Sale Invoice : SOE.OE_VAR2 (Marked = 1; Unmarked = 0 )

Internal movements: SOE.PARINTG (Marked = 1; Unmarked = 0 )

Balance Implementation: SOE_OE_VAR3(Marked = 1; Unmarked = 0 )

These options are valid only for sending from Protheus to PC-Factory. For request (request of PC-Factory) will not have filters.

Synchronization - PCPA111

The synchronization is the process that is used to populate or update the base of PC-Factory with data from Protheus. It will work the same manner the other routines of integration do, by integrating a XML message to WebService of PC-Factory, following the parameterizations defined in PCPA109. The only difference is that all data of the table being integrated are viewed (following the filters) instead of only one record.

Pendencies - PCPA110

Routine to resend messages not sent to PC-Factory system, whether they are pendencies or mistakes. The routine also enables to query the messages sent (delivery LOG).

To check pendencies and log of messages moved between the systems:

- Structure Register

- Product/Item

- Location of Stock (deposits)

- Resource PCP

- Production orders (Operations, Scripts, Components, Splits)

- Shop floor resources - Tools, Team and Operator

- Tools

- Shop Floor Machinery

- Scripts - Operations

- Addresses

- Balance

With the following options:

- Reprocess:

For each line selected, the messages must be sent. - Delete

Delete selected records - Save XML

This option enables to save the XML in a directory location of the machine that is processing the pendencies routine. - Update

Redo the search of records, updating data on screen

Import Log - PCPA112

When receiving data from PC-Factory, Webservice Protheus saves information so they are queried (SOG table). Find the list of movements generation LOG below:

- Production annotation

- Stoppage annotation

- Scrap Reason

- Stoppage Reason

- Stock movements

- Transfer

Messages

Registers

Transaction Item: Item_3_001.xsd

Message Identifier: Item

Version: 3_001

Protheus Module: SiGAPCP

Sending Type: Synchronous

| Message | Tag | Description | Table/Field: Protheus | Type | Table/Field: PC-Factory | Type |

|---|---|---|---|---|---|---|

| BusinessContentType | CompanyId | Code of the Logged Company

| CHAR(02) | |||

| BranchId | Branch Code | SB1.B1_BRANCH | CHAR(02) | TBLInProduct.PlantCode | CHAR(15) | |

| CompanyInternalId | Company+Branch | COMPANY + SB1.B1_BRANCH | ||||

| Code | Product Code | SB1.B1_COD | CHAR(15) | TBLInProduct.Code | CHAR(20) | |

| Name | Product Description | SB1.B1_DESC | CHAR(30) | TBLInProduct.Name | CHAR(70) | |

| InternalId | Company+branch+product code | COMPANY + SB1.B1_BRANCH + SB1.B1_COD | ||||

| ShortName | Short name | SB1.B1_DESC | CHAR(30) | TBLInProduct.SecondName | CHAR(30) | |

| Active | Item active? | SB1.B1_ACTIVE | CHAR(01) | TBLInProduct.FlgEnable | SMALLINT | |

| UnitOfMeasureCode | Unit of Measure | SB1.B1_UM | CHAR(02) | TBLInProduct.Unit1code | CHAR(05) | |

| UnitOfMeasureInternalId | Company+branch+unit of measure | COMPANY + SB1.B1_BRANCH + SB1.B1_UM | ||||

| StockGroupCode | Group of Stock | SB1.B1_GROUP | CHAR(04) | |||

| StockGroupInternalId | Company+branch+stock group | COMPANY + SB1.B1_BRANCH + SB1.B1_GROUP | ||||

| StockGroupDescription | Description of stock group | SBM.BM_DESC | CHAR(30) | |||

| StandardWarehouseCode | Location of Stock | SB1.B1_LOCPAD | CHAR(02) | |||

| StandardWarehouseInternalId | Company+branch+location of stock | COMPANY + SB1.B1_BRANCH + SB1.B1_LOCPAD | ||||

| StandardWarehouseDescription | Location of Stock Description | NNR.NNR_DESCRI | CHAR(40) | |||

| EconomicLot | Economic lot | SB1.B1_LE | DEC(12,2) | |||

| MinimumLot | Minimum lot | SB1.B1_LM | DEC(12,2) | |||

| FamilyCode | Family | SB1.B1_FPCOD | CHAR(10) | TBLInProduct.FamilyProductCode | CHAR(15) | |

| FamilyInternalId | Company+branch+family | COMPANY + SB1.B1_BRANCH + SB1.B1_FPCOD | ||||

| FamilyDescription | Description of family | SYC.YC_NAME | CHAR(40) | TBLInProduct.FamilyProductName | CHAR(30) | |

| NetWeight | Item Weight | SB1.B1_WEIGHT | DEC(11,4) | |||

| GrossWeigh | Gross Weight | SB1.B1_PESBRU | DEC(11,4) | |||

| Trail | Trace | SB1.B1_TRACE | CHAR(01) | |||

| BinControl | Controls Address | SB1.B1_LOCALIZ | CHAR(01) | |||

| SecondUnitOfMeasureCode | Second Unit of Measure | SB1.B1_SEGUM | CHAR(02) | TBLInProduct.Unit2Code | CHAR(20) | |

| SecondUnitOfMeasureInternalId | Company+branch+ sec. measure unit | COMPANY + SB1.B1_BRANCH + SB1.B1_SEGUM | ||||

| MultiplicationFactorValue | Factor of conversion | SB1.B1_CONV | DEC(5,2) | TBLInProduct.Unit2Factor | DEC(8,4) | |

| ProductType | Type of Item | SB1.B1_TYPE | CHAR(02) | TBLInProduct.ProductTypeCode | CHAR(15) | |

| PackingQuantity | Quantity Package | SB1.B1_QE | NUM(09) | TBLInProduct.QtyPackage | DEC(19,4) | |

| CostCenterCode | Cost Center | SB1.B1_CC | CHAR(09) | TBLInProduct.CostCenterCode | CHAR(20) | |

| StockControlType | Control of item stock | CHAR(01) |

Note:

- If it is an undefined type, it must be saved as GENERIC. Example: Type = SAMPLER.

- The tag StockControlType can be, 1=Serial;2=No. of Series;3=Lote;4=Reference. If field B1_RASTRO is S=SubLote or L=Lote, save as '3'. If field B1_LOCALIZ is S=Yes, save as 2. The product can control lot and series at the same time, being registered in the tags TRIAL and BINCONTROL.

Deposit Transaction: Warehouse_1_001.xsd

Message Identifier: Warehouse

Version: 1_001

Protheus Module: SiGAPCP

Sending Type: Synchronous

| Message | Tag | Description | Table/Field: Protheus | Type | Table/Field: PC-Factory | Type |

|---|---|---|---|---|---|---|

| BusinessContentType | CompanyId | Company Code | CHAR(02) | TBLInWarehouse.Extcode | CHAR(20) | |

| BranchId | Branch Code | NNR.NNR_BRANCH | CHAR(02) | TBLInWarehouse.PlantCode | CHAR(15) | |

| CompanyInternalId | Company+Branch | COMPANY + NNR.NNR_BRANCH | ||||

| Code | Location of Stock Code(warehouse/deposit) | NNR.NNR_CODE | CHAR(02) | TBLInWarehouse.Code | CHAR(15) | |

| InternalId | Company+Branch+location code | COMPANY + NNR.NNR_BRANCH + NNR.NNR_CODE | ||||

| Description | Location of Stock Description (warehouse/deposit) | NNR.NNR_DESCRI | CHAR(20) | TBLInWarehouse.Name | CHAR(15) | |

| Active | Location of Stock Active? | TRUE | CHAR(01) | TBLInWarehouse.FlgEnable | SMALLINT | |

| Type | Location of Stock Type | NNR.NNR_TYPE | CHAR(01) | |||

| WarehouseClassification | Classification | NNR.NNR_INTP | CHAR(01) |

Transaction Resource PCP / Machine SFC: Machine_1_000.xsd

Message Identifier: Machine

Version: 1_000

Protheus Module: SIGAPCP, SIGASFC

Sending Type: Synchronous

| Message | Tag | Description | Table/Field: Protheus PCP | Table Field: Protheus SFC | Type | Table/Field: PC-Factory | Type |

|---|---|---|---|---|---|---|---|

| BusinessContentType | |||||||

| Code | Machine Code | SH1.H1_CODE | CYB.CYB_CDMQ | CHAR(20) | TBLInResource.code | CHAR(15) | |

| Description | Machine Description | SH1.H1DESCRI | CYB.CYB_DSMQ | CHAR(40) | TBLInResource.Name TBLInResource.Nickname | CHAR(20) | |

| WorkCenterCode | Work Center Code | SH1.H1_CTRAB | CYB.CYB_CDCETR | CHAR(10) | TBLInResource.ManagerGrpCode | CHAR(15) | |

| WorkCenterDescription | Work Center Description | SHB.HB_NAME | CYB.CYB_DSCETR | CHAR(40) | TBLInResource.WorkCenterDescription | CHAR(15) | |

| CostCenterCode | Cost Center Code | SH1.H1_CCUST | CYB.CYB_CDCECS | CHAR(20) | |||

| ProcessorType | Type of Processing | CYB.CYB_TPPC 1=Monoprocess;2=By Batch; 3=Multiple Processes;4=Manual | CHAR(01) | ||||

| LaborType | Type MOD | CYB.CYB_TPMOD 1=Does not Report;2=Operator;3=Team | CHAR(01) | ||||

| VolumeMachineQuantity | Machine Volume Quantity | CYB.CYB_QTVMMQ | DEC(12,4) | ||||

| EfficiencyMachineValue | Machine Efficiency | CYB.CYB_VLEFMQ | DEC(05,2) | ||||

| OperatorMachineQuantity | Machine Operator Quantity | CYB.CYB_QTOEMQ | NUM(02) | ||||

| SimultaneousActivityQuantity | Quantity Simultaneous Operations | CYB.CYB_QTATSM | NUM(03) | ||||

| IsSetup | It is set up | CYB.CYB_LGSU | BOOLEAN | ||||

| IsOverlapReport | Overlaps Annotation | CYB.CYB_LGOVRP | BOOLEAN | ||||

| ProductionAreaCode | Production Area | CYB.CYB_CDARPO | CHAR(10) | ||||

| InitialValidateDate | Validity Initial Date | CYB.CYB_DTBGVD | DATE | ||||

| FinalValidateDate | Validity End Date | CYB.CYB_DTEDVD | DATE | ||||

| ListOfResources | |||||||

| ResourceType | Resource Type | CYC.CYC_TPRC 1=Operator;2=Tool; 3=Team;4=Equipment | CHAR(01) | ||||

| ResourceCode | Resource Code | CYC.CYC_CDRC | CHAR(20) | TBLInUser.Code | CHAR(30) | ||

| ResourceName | Resource Name | CYC.CYC_NMRC | CHAR(40) | TBLInUser.Name TBLInUser.Nickname | CHAR(60) | ||

| UnitTimeType | Measure Time Type | CYC.CYC_TPUNTE 1=Hours;2=Minutes;3=Seconds | CHAR(01) | ||||

| StartExpirationDate | Validity Start Date | CYC.CYC_DTBGVD | DATE | ||||

| EndExpirationDate | Validity End Date | CYC.CYC_DTEDVD | DATE | ||||

| CycleQuantity | Number Cycles | CYC.CYC_QTCI | DEC(11,4) | ||||

| IsTimeActivity | Determines time | CYC.CYC_LGTEAT | BOOLEAN | ||||

| ListOfProductionShifts | |||||||

| ProductionShiftCode | Code Shift Model | CYL.CYL_CDTN | CHAR(08) | ||||

| ProductionShiftDescription | Description Shift Model | CYL.CYL_DSTN | CHAR(40) | ||||

| BeginDate | Validity Start Date | CYL.CYL_DTVDBG | DATE | ||||

| EndDate | Validity End Date | CYL.CYL_DTVDED | DATE |

In PCP, the machines are registered in the routine of resources MATA610 and in the Shop Floor, the routine is SFCA002. Nomenclature is also changed. When using Shop Floor, it is named MACHINE. When using only PCP. it is RESOURCE. The routine of parameters PCPA109 is ready to present the name according to the use of the system.

SFC Resource Transaction: Resource_1_000

Message Identifier: Resource

Version: 1_000

Protheus Module: SIGAPCP

Sending Type: Synchronous

Message | Tag | Description | Table/Field: Protheus PCP | Table Field: Protheus SFC | Type | Table/Field: PC-Factory | Type |

BusinessContentType |

|

|

|

|

|

| |

| Code | Resource Code | SH4.H4_CODE | CYH.CYH_CDRC | CHAR(06) | TBLTooling.Code | CHAR(15) |

| Name | Resource Name | SH4.H4_DESCRI | CYH.CYH_NMRC | CHAR(40) | TBLTooling.Name | CHAR(50) |

| Type | Resource Type | 1=Operator;2=Tool; 3=Team;4=Equipment.

| CYH.CYH_TPRC 1=Operator;2=Tool; 3=Team;4=Equipment | CHAR(25) |

|

|

| ProductionAreaCode | Production Area |

| CYH.CYH_CDARPO | CHAR(10) |

|

|

| ProductionAreaDescription | Production area description |

| CYA.CYA_DSARPO | CHAR(40) |

|

|

ItemComponentType |

|

|

|

|

|

|

|

| ProductionShiftNumber | Shift | SH4.H4_TURNO | CYH.CYH_NRTN | CHAR(05) |

|

|

| LaborCode | MOB | Fixed '1' | CYH.CYH_CDMOD | CHAR(08) |

|

|

| StartExpirationDate | Start validity date | Current Date | CYH.CYH_DTVDBG | DATE | TBLTooling.Period | INT |

| EndExpirationDate | End Validity Date |

| CYH.CYH_DTVDED | DATE | TBLTooling.Period | INT |

| UnitCycleQuantity | Units Cycles |

| CYH.CYH_QTUNCI | NUM(07) |

|

|

| ToolCode | Tool |

| CYH.CYH_CDMPRC | CHAR(15) |

|

|

| ToolDescription | Tool Description |

| CYH.CYH_DSMPRC | CHAR(40) |

|

|

Note:

- The Resource in the PCP indicates the machine, in the shop floor indicates toosl, operator etc;

- When origin is PCP the tag Type (Resource Type) is generated in fixed value '2';

- When origin is PCP the tag UnitCycleQuantity (Cycles Unit) is generated in fixed value '1';

- When origin is PCP the tag UnitCycleQuantity (Cycles Unit) is generated in fixed value '1';

- When origin is PCP the tag StartExpirationDate (Start Validity) is generated with date of message generation;

- When origin is PCP the tag EndExpirationDate (End Validity) is generated in fixed value '1';

Current date (dDataBase) + lifespan of tool (H4_VIDAUTI). Consider type of lifec ycle (H4_TIPOVID) - D=Days;H=Hours;M=Month;A=Year

Transaction Structure: ItemStructure_1_000.xsd

Message Identifier: ItemStructure

Version: 1_000

Protheus Module: SiGAPCP

Sending Type: Synchronous

| Message | Tag | Description | Table/Field: Protheus | Type | Table/Field: PC-Factory | Type |

|---|---|---|---|---|---|---|

| BusinessContentType | CompanyId | Company Code | CHAR(02) | |||

| CompanyInternalId | Company+Branch | COMPANY + SG1.G1_BRANCH | ||||

| ItemInternalId | Company+Branch+code parent item | COMPANY + SG1.G1_BRANCH + SG1.G1_COD | ||||

| ItemCode | Code parent item | SG1.G1_COD | CHAR(15) | TBLInWOHD.ProductCode TBLInWOHD.WOCode | CHAR(30) | |

| ItemAmount | Base quantity of parent item | SB1.B1_QB | NUM(07) | TBLInWOHD.TotalQTY | DEC(19,4) | |

| ItemComponentType | ||||||

| ItemSequence | Sequence of component | SG1.G1_TRT | NUM(05) | TBLInBillMat.BillMatExtCode | CHAR(20) | |

| ItemComponentCode | Code item component | SG1.G1_COMP | CHAR(15) | TBLInBillMat.ProductCode | CHAR(20) | |

| ItemComponentInternalId | Internal Id of Item Component | COMPANY + SG1.G1_BRANCH + SG1.G1_COMP | ||||

| InitialDate | Validity Initial Date | SG1.G1_INI | DATE | TBLInWOHD.DtPlanStart | DATETIME | |

| FinalDate | Validity End Date | SG1.G1_FIM | DATE | TBLInWOHD.DtPlanEnd | DATETIME | |

| IsGhostMaterial | Indicates whether it is ghost | SB1.B1_FANTASM | BOOLEAN ( FALSE ou TRUE) | |||

| ItemComponentAmount | Quantity of component item | SG1.G1_QUANT | DEC(12,6) | |||

| LossFactor | Factor of loss | SG1.G1_LOSS | DEC(05,2) | |||

| Scriptcode | Code of Script | SGF.GF_SCRIPT | CHAR(02) | TBLInWOHD.ExtCode | CHAR(20) | |

| ScriptAlternative | Alternative of Script | -- | ||||

| ActivityIntenalID | ID Operation | -- | ||||

| ActivityCode | Code of Operation | SGF.GF_OPERAC | CHAR(02) | TBLInWodet.Code | CHAR(10) | |

| ActivityComponentSequence | Sequence of component in the operation | SGF.GF_TRT | NUM(03) |

Script Transaction - Item Operations: ItemScript_1_000.xsd

Message Identifier: ItemScript

Version: 1_000

Protheus Module: SiGAPCP

Sending Type: Synchronous

| Message | Tag | Description | Table/Field: Protheus | Type | Table/Field: PC-Factory | Type |

|---|---|---|---|---|---|---|

| BusinessContentType | ItemCode | Item Code | SG2.G2_PRODUCT | CHAR(15) | TBLInWOHD.ProductCode TBLInWOHD.WOCode | CHAR(20) |

| ItemDescription | Description of item | SB1.B1_DESC | CHAR(40) | |||

| ItemInternalId | Company[Branch|Item | COMPANY + SG2.G2_BRANCH + SG2.G2_PRODUCT | ||||

| ScriptCode | Code of Scripto | SG2.G2_CODE | CHAR(02) | |||

| ScriptDescription | Description Script | -- | CHAR(40) | |||

| ScriptAlternative | Script Alternative | -- | CHAR(02) | |||

| ListOfActivity | ||||||

| ActivityInternalID | ID Operation | SG2.R_E_C_N_O_ | NUM(05) | |||

| ActivityCode | Code of Operation | SG2.G2_OPERAC | CHAR(02) | TBLInWodet.Code | CHAR(10) | |

| ActivityDescription | Description Operation | SG2.G2_DESCRI | CHAR(60) | TBLInWodet.Name | CHAR(40) | |

| MachineCode | Machine Code | SG2.G2_RESOURCE | CHAR(06) | TBLInWodet.Resource | CHAR(15) | |

| ToolCode | Code Tool | SG2.G2_TOOL | CHAR(06) | |||

| ActivityType | Type Operation | 1 = Executes operation; 2 = Does not execute. | CHAR(01) | |||

| WorkCenterCode | Code Work Center | SG2.G2_CTRAB | CHAR(06) | TBLInWodet.ManagerGrpCode | CHAR(15) | |

| WorkCenterInternalId | Id Work Center | COMPANY + SG2.G2_BRANCH + SG2.G2_CTRAB | ||||

| UnitItemNumber | Standard Lot | SG2.G2_LOTEPAD | NUM(06) | TBLInWodet. StdSpeed | DEC(28,23) | |

| TimeResource | Time Resource | 0 | TBLInWodet. StdSpeed | DEC(28,23) | ||

| TimeMachine | Time Machine | SG2.G2_TEMPAD | DEC(05,2) | TBLInWodet. StdSpeed | DEC(28,23) | |

| TimeSetup | Time Preparation | SG2.G2_SETUP | DEC(05,2) | TBLInWodet. SetUpTime | INT | |

| UnitTimeType | Type Unit Time | 1 = Hours;2=Minutes;3=Seconds;4=Days | TBLInWodet. StdSpeedFormat | TINYINT | ||

| ScriptAlternative | Alternative | SG2.G2_ROTALT | CHAR(02) | |||

| InitialDate | Initial Date | SG2.G2_DTINI | DATE | TBLInWodet.DtPlanStart | DATETIME | |

| FinalDate | Final Date | SG2.G2_DTFIM | DATE | TBLInWodet.DtPlanEnd | DATETIME | |

| PercentageScrapValue | % Scrap | -- | ||||

| PercentageValue | Proportion | -- | ||||

| ResourceQuantity | Quantity Resource | -- |

Note:

- The tag ActivityType (Operation Type) is generated with fixed value '1';

- The tag ActivityType (Time Unit Type) is generated with fixed value '1';

- The tag ListOfPertOrders is not generated for Protheus;

- In the deletion of a script, do not delete if there is integrity with the routine of OPERATIONS x COMPONENTS, MATA637. In this case, you do not need to send any message to PC-Factory;

- When adding, editing or deleting data from MATA637, structure message is sent, ItemStructure.

Addresses Transaction: AdressStock_1_000.xsd

Message Idenfier: AdressStock

Version: 1_000

Protheus Module: SiGAPCP

Sending Type: Synchronous

| Message | Tag | Description | Table/Field: Protheus | Type | Table/Field: PC-Factory | Type |

|---|---|---|---|---|---|---|

| BusinessContentType | WarehouseCode | Warehouse/Deposit | SBE.BE_LOCAL | CHAR(02) | TBLInAddress.WarehouseCode | CHAR(15) |

| LocationCode | Address/Location | SBE.BE_LOCALIZ | CHAR(15) | TBLInAddress.Code | CHAR(15) | |

| AdressInternalId | Full Key address | COMPANY + SBE.BE_BRANCH + SBE.BE_LOCAL + SBE.BE_LOCALIZ | ||||

| AdressStockDescription | Description of address | SBE.BE_DESCRIP | CHAR(30) | TBLInAddress.ExtCode | CHAR(20) |

Balance Transaction: ItemStockLevel_1_000.xsd

Message Identifier: ItemStockLevel

Version: 1_000

Protheus Module: Various

Sending Type: Synchronous

| Message | Tag | Description | Table/Field: Protheus | Type | Table/Field: PC-Factory | Type |

|---|---|---|---|---|---|---|

| BusinessContentType | ItemCode | Code of product | SB2.B2_COD | CHAR(15) | TBLInMovMat.ProductCode | CHAR(20) |

| ItemDescription | Description of item | SB1.B1_DESC | CHAR(30) | |||

| ListOfStock |

| |||||

| ReferenceCode | Reference | -- | ||||

| WarehouseCode | Deposit/Location of stock/Warehouse | SB2.B2_LOCAL | CHAR(02) | TBLInMovMat.WarehouseCode | CHAR(15) | |

| LotCode | Number of Lot | SB8.B8_LOTECTL | CHAR(10) | TBLInMovMat.LotCode | CHAR(41) | |

| SubLotCode | Sub-Lot | SB8.B8_NUMBATCH | CHAR(06) | |||

| NumberSeries | Number of Series | SBF.BF_NUMSERI | CHAR(20) | |||

| AddressCode | Address/Location | SBF.BF_LOCAL | CHAR(15) | TBLInMovMat.AddressCode | CHAR(15) | |

| LotDueDate | Validity Date | SB8.B8_DTVALID | DATE | TBLInMovMat.LotDtValidity | DATETIME | |

| CurrentStockAmount | Balance of stock | SB2.B2_QATU SB8.B8_BALANCE SBF.BF_QUANT | DEC(12,2) | |||

| BookedStockAmount | Reserved Quantiy | SB2.B2_RESERVATION SB8.B8_ALLOCATION SBF.BF_ALLOCATION | DEC(12,2) | |||

| AvailableStockAmount | Balance available | SB2.B2_QATU - SB2.B2_RESERVA SB8.B8_SALDO - SB8.B8_ALLOCATION SBF.BF_QUANT - SBF.BF_ALLOCATION | DEC(12,2) | |||

QuantityUpdated | Updated Quantity | DEC(12,2) | TBLInMovMat.Qty | DEC(18,2) | ||

| InputOutput | Input or Output | 1 = Input or 2 = Output | CHAR(01) | TBLInMovMat.Classification | CHAR(15) |

Note:

- When updating new balance in ERP, message is sent to PC-Factory.

Transactions generating movement of stock and executing balance updating routines activating integration:

Inbound Inv. - Function B2ATUCOMD1

Sale Inv. - Function B2ATUCOMD2 Internal Transac. - Function B2ATUCOMD3 - When the balance is updated by an update of PC-Factory do not generated the balance updating message. When the origin of the balance change is TOTVSMES, message is not generated.

In production annotation message, tag Product Name indicates what is sent to record. For TOTVS MES, this information is saved in SH6.H6_OBSERVA = 'TOTVSMES'.

If the movement is internal, it is registered in SD3.D3_OBSERVA = 'TOTVSMES'. - The field QuantityUpdated corresponds to the updated quantity, that is, quantity being moved.

- The field InputOutput indicates if the movement is input or output.

- When the item controls address (B1_LOCALIZ), the balance message must be generated only in the confirmation of MATA265, routine executing the address.

- The routines of initial balance of PCP and Stock, MATA220 and MATA805 also generated the balance message.

Waste Reason Transaction: WasteReason_1_000.xsd

Message Identifier: WasteReason

Version: 1_000

Protheus Module: SIGAPCP/SIGASFC

Sending Type: Synchronous

| Message | Tag | Description | Table/Field: Protheus PCP | Table Field: Protheus SFC | Type | Table/Field: PC-Factory | Type |

|---|---|---|---|---|---|---|---|

| BusinessContentType | Code | Scrap Code | SX5.X5_KEY | CYO.CYO_CDRF | CHAR(08) | TBLOutScrap.Code | CHAR(15) |

| Description | Description of Scrap | X5_DESCRI X5_DESCSPA X5_DESCENG | CYO.CYO_DSRF | CHAR(40) | TBLOutScrap.Name | CHAR(30) | |

| IsRework | Rework |

| CYO.CYO_LGRT | BOOLEAN | |||

| IsScrapMaterial | Material Scrap | SBE.BE_DESCRIC | CYO.CYO_LGRFMP | BOOLEAN |

Note:

- When no is integrated with Shop Floor, MV_INTSFC equal to '0' the scrap is registered in generic table SX5.

- It must search in SX5 table according to command below:

select X5_CHAVE from sx5990 where X5_TABLE = '43'

Where:

- Code of reason is X5_CHAVE

Table of reason is '43'. - When it is integrated with Shop Floor, MV_INTSFC equal to '1' is generated only the table of Shop Floor - CYO. Routine SFCA003. If in the message there is no indicator of scrap or rework, consider scrap (CYO_LGRFMP = 'T').

- Waste reasons have different sizes in tables. Validate it if receipt code does not exceed the size of columns in Protheus.

- When uses the SIGAPCP it must validate a SX5.X5_CHAVE and SBC.BC_MOTIVO.

- When uses the SIGASFC validate against the CYO.CYO_CDRF, CY0.CY0_CDRF and SBC.BC_REASON.

Stop Reason Transaction: StopReason_1_000.xsd

Message Identifier: StopReason

Version: 1_000

Protheus Module: SIGAPCP/SIGASFC

Sending Type: Synchronous

Message | Tag | Description | Table/Field: Protheus PCP | Table Field: Protheus SFC | Type | Table/Field: PC-Factory | Type |

BusinessContentType | Code | Stoppage Reason Code | SX5.X5_KEY | CYN.CYN_CDSP | CHAR(10) | TBLOutResourceStatus.Code | CHAR(05) |

| Description | Stoppage Description | X5_DESCRI X5_DESCSPA X5_DESCENG | CYN.CYN_DSSP | CHAR(40) | TBLOutResourceStatus.Name | CHAR(30) |

| IsEfficiency | Change Efficiency | -- | -- |

|

|

|

| IsEmailEquipment | E-mail Planner | -- | -- |

|

|

|

| IsServiceRequest | Issue Service Request | -- | -- |

|

|

|

| IsSetup | Setup Stoppage | -- | -- |

| TBLOutResourceStatus.FlgSetup | SMALLINT |

Note:

- When no is integrated with Shop Floor, MV_INTSFC equal to '0' the stoppage reason is registered in generic table SX5.

- It must search in SX5 table according to command below:

select X5_CHAVE from sx5990 where X5_TABELA = '44'

Where:

- Code of reason is X5_CHAVE

Table of reason is '44'. - When it is integrated with Shop Floor, MV_INTSFC equal to '1' is generated only the table of Shop Floor - CYN. Routine SFCA004.

- Stoppage reasons have different sizes in tables. Validate it if receipt code does not exceed the size of columns in Protheus.

When it uses the SIGAPCP it must validate against the SX5.X5_CHAVE and SH6.H6_REASON

When it uses the SIGASFC validate against the CYN.CYN_CDSP, CYX.CYX_CDSP and SH6.H6_REASON

Production Order Transaction: ProductionOrder_2_004.xsd

Message Identifier: ProductionOrder

Version: 2_003

Module Protheus: SIGAPCP

Sending Type: Synchronous

| Message | Tag | Description | Table/Field | Type | Table/Field: PC-Factory | Type |

|---|---|---|---|---|---|---|

| BusinessContentType | Number | Number Production Order | SC2.C2_NUM + SC2.C2_ITEM + SC2.C2_SEQUEN | CHAR(20) | TBLInWOHD.Code | CHAR(41) |

| ProductionOrderUniqueID | Company+Branch+Production Order | COMPANY + SC2.C2_BRANCH + SC2.C2_NUM + SC2.C2_ITEM + SC2.C2_SEQUEN | CHAR(30) | |||

| ItemCode | Code Item | SC2.C2_PRODUCT | CHAR(15) | TBLInWOHD.ProductCode | CHAR(20) | |

| ItemDescription | Description Item | SB1.B1_DESC | CHAR(40) | |||

| Type | Type of Order | 1= Internal; 2=External; 3=Internal/External; 4=Rework; 5=Fixing; 6=Maintenance; 7=Fixed Asset; 8=Tooling; 9=Reuse

| CHAR(01) | TBLInWOHD.WoTypeCode | CHAR(20) | |

| Quantity | Quantity | SC2.C2_QUANT | DEC(12,2) | TBLInWOHD.TotalQty | DEC(19,4) | |

| ReportQuantity | Quantity Reported | SC2.C2QUJE | DEC(12,2) | |||

| UnitOfMeasureCode | Unit of Measure | SC2.C2_UM | CHAR(02) | TBLInWoDet.Unit1Code | CHAR(05) | |

| RequestOrderCode | Request Code Production Order | SC2.C2_ORDER | CHAR(06) | |||

| StatusOrderType | Order Status | Estimated/Opened = 1 Started = 6 Partial/Total Closed = 7 Idle = 9 | CHAR(01) | TBLInWOHD.Status | SMALLINT | |

| WarehouseCode | Code Deposit | SC2.C2_LOCAL | CHAR(02) | TBLInWOHD.AuxCode1 | CHAR(20) | |

| EndOrderDateTime | End Date Production Order CP | SC2.C2_DATPRF | DATE | TBLInWOHD.DtPlanEnd | DATETIME | |

| StartOrderDateTime | Start Date Production Order CP | SC2.C2_DATPRI | DATE | TBLInWOHD.DtPlanStart | DATETIME | |

| AbbreviationProviderName | Name Customer | SC5.C5_CLIENTE ( SA1.A1_NOME) | CHAR(30) | |||

| ScriptCode | Code Script | SC2.C2_SCRIPT | CHAR(02) | |||

| ReportOrderType | Type of Report | 1 = Order; 2 = Operations; 3 = Control Point; 4 = Item

| CHAR(01) | |||

| ListOfActivityOrders | ||||||

| ProductionOrderNumber | Production Order | SC2.C2_NUM + SC2.C2_ITEM + SC2.C2_SEQUEN | CHAR(20) | TBLInWoDet.Wocode | CHAR(10) | |

| ActivityID | ID of Record | RECNO (SG2,SHY ou SH8) | CHAR(10) | |||

| ActivityCode | Code Operation | SG2.G2_OPERAC SHY.HY_OPERAC SH8.H8_OPER | CHAR(02) | TBLInWoDet.WODetCode+Split | CHAR(10) | |

| ActivityDescription | Description Operation | SG2.G2_DESCRI | CHAR(40) | TBLInWoDet.WODetName | CHAR(30) | |

| Split | Split of operation | SH8.H8_DESDOBR | CHAR(04) | |||

| ItemCode | Code of item | SC2.C2_PRODUCT | CHAR(15) | |||

| ItemDescription | Description of item | SB1.B1_DESC | CHAR(40) | |||

| ActivityType | Type Operation | 1 - Register ; 2-Does not register | CHAR(01) | |||

| WorkCenterCode | Code Work Center | SG2.G2_CTRAB SHY.HY_CTRAB SH8.H8_CTRAB | CHAR(06) | TLBInWODet.ManagerGrpCode | CHAR(15) | |

| WorkCenterDescription | Description Work Center | SHB.HB_NOME | CHAR(30) | |||

| UnitTimeType | Type Unit Time | 1 - Hours; 2 - Minutes; 3- Seconds; 4 - Days | CHAR(01) | TLBInWODet.StdSpeedFormat | TINYINT | |

| TimeResource | Time Resource (Standard time for lot) | SG2.G2_TEMPAD | DEC(05,2) | TLBInWODet.StdSpeed | DEC(28,23) | |

| TimeMachine | Time Machine (Time to order) | SG2.G2_TEMPAD * SC2.C2_QUANT SHY.HY_TIME SH8.H8_HRINI - SH8.H8_HRFIM | DEC(14,4) | TLBInWODet.StdSpeed | DEC(28,23) | |

| TimeSetup | Tiem Setup | SG2.G2_SETUP SHY.HY_TIMES SH8.H8_SETUP | DEC(15,4) | TLBInWODet.SetUpTime | INT | |

| TimeMOD | Time Man | -- | ||||

| TimeIndMES | Iindicator of time in MES | 1 = Machine Time; 2 = Labor Time; 3 = Choice by MES. | CHAR(01) | |||

| ScriptCode | Code Script | SG2.G2_CODE SHY.HY_SCRIPT SH8.H8_SCRIPT | CHAR(02) | |||

| LaborCode | Code Direct Labor | MOD+CC | CHAR(08) | |||

| UnitItemNumber | Standard Lot | SG2.G2_LOTEPAD | NUM(05) | TLBInWODet.StdSpeed | DEC(28,23) | |

| IsActivityEnd | Last Operation | In the last operation, TRUE. Otherwise, FALSE. | BOOLEAN | TLBInWODet.ReportTrigger | TINYINT | |

| MachineCode | Machine Code | SG2_RESOURCE SHY_RESOURCE H8_RESOURCE | CHAR(06) | |||

| StartPlanDateTime | Date/Time Start Schedule | SHY.HY_HORAINI SC2.C2_DATPRI SH8.H8_DTINI | DATE | TLBInWODet.StartPlanDateTime | DATETIME | |

| EndPlanDateTime | Date/Time End Schedule | SHY.HY_HORAFIM SC2.C2_DATPRF SH8.H8_DTFIM | DATE | TLBInWODet.EndPlanDateTime | DATETIME | |

| ProductionQuantity | Quantity to produce in operation | SHY.HY_QUANT SH8.H8_QUANT SC2.C2_QUANT | DEC(12,2) | TLBInWODet.Qty | DEC(19,4) | |

| ActivityQuantity | Quantity of operation | SHY.HY_QUANT SH8.H8_QUANT SC2.C2_QUANT | DEC(12,2) | |||

| UnitActivityCode | Unit of measure | SB1.B1_UM | CHAR(02) | TLBInWODet.Unit1Code | CHAR(5) | |

| SecondUnitActivityCode | Second unit of measure in operation | -- | TLBInWODet.Unit2Code | CHAR(5) | ||

| SecondUnitActivityFactor | Conversor Factor for second unit in operation | -- | TLBInWODet.Unit2Factor | DEC(8,4) | ||

| ResourceQuantity | Quantity of resources | SG2.G2_MAOOBRA SHY.HY_MAOOBRA | NUM(03) | |||

| ListOfMaterialOrders | ||||||

| ProductionOrderNumber | Production Order | SC2.C2_NUM + SC2.C2_ITEM + SC2.C2_SEQUEN | CHAR(20) | TBLInBillMat.Wocode | CHAR(41) | |

| MaterialID | ID of reservation record | SD4.R_E_C_N_O_ | CHAR(10) | |||

| MaterialCode | Code Reservation Item | SD4.D4_COD | CHAR(15) | TBLInBillMat.ProductCode | CHAR(20) | |

| MaterialDescription | Description of Item | SB1.B1_DESC | CHAR(40) | |||

| ScriptCode | Code Script | SD4.D4_SCRIPT | CHAR(02) | |||

| ActivityCode | Code Operation | SD4.D4_OPERAC | CHAR(02) | TBLInBillMat.WODetCode | CHAR(10) | |

| WarehouseCode | Code Deposit | SD4.D4_LOCAL | CHAR(02) | TBLInBillMat.ExtCode | CHAR(20) | |

| MaterialDate | Date Reservation | SD4.D4_DATE | DATE | |||

| MaterialQuantity | Quantity of Reservation | SD4.D4_QUANT | DEC(12,2) | TBLInBillMat.TotalQty | DEC(19,4) | |

| LotCode | Lot | SD4.D4_LOTECTL | CHAR(10) | |||

| PertMaterialNumber | Sequence of item | SD4.D4_TRT | CHAR(03) | |||

| RequestType | Type of Request | SB1.B1_APROPRI | CHAR(01) | TBLInBillMat.Comments | CHAR(500) | |

| ||||||

| WarehouseCode | Code Deposit | SD4.D4_LOCAL | CHAR(02) | TBLInMovMat.WarehouseCode | CHAR(15) | |

| LotCode | Code Lot | SD4.D4_LOTECTL SDC.DC_LOTECTL | CHAR(10) | TBLInMovMat.LotCode | CHAR(41) | |

| LocationCode | Location/Address | SDC.DC_LOCALIZ | CHAR(15) | TBLInMovMat.AddressCode | CHAR(15) | |

| ActivityCode | Code Operation | SD4.D4_OPERAC | CHAR(02) | TBLInMovMat.WoDetCode | CHAR(10) | |

| ScriptCode | Code Script | SD4.D4_SCRIPT | CHAR(02) | |||

| AllocationQuantity | Allocated Quantity | SD4.D4_QUANT SDC.DC_QUANT | DEC(12,2) | TBLInMovMat.Qty | DEC(19,4) | |

| AllocationType | Type Allocation | 1 = Adds;2=Decreases;3=Absolute Value | CHAR(01) | TBLInMovMat.AllocationType | INT | |

| SubLoteCode | Sub Lot | SD4.D4_NUMLOTE SDC.DC_NUMLOTE | CHAR(06) | |||

| NumberSeries | Number of Series | SDC.DC_NUMSERI | CHAR(20) | |||

| LotDueDate | Validity Date | SD4.D4_DTVALID | DATE | TBLInMovMat.LotDtValidity | DATETIME | |

| ListOfQuotaActivity | ||||||

| ProductionOrderNumber | Number Production Order | CY9.CY9_NRORPO | CHAR(20) | |||

| ControlType | Selection Split | -- | ||||

| ActivityID | ID Operation | CY9.CY9_CDAT | CHAR(10) | |||

| ItemCode | Code of item | CYY.CYY_CDAC | CHAR(15) | |||

| ItemDescription | Description of item | CYY.CYY_DSAC | CHAR(40) | |||

| StartActivityDateTime | Date/Time Start Activity | CYY.CYY_DTBGAT / CYY.CYY_HRBGAT | DATETIME | TBLInWODet.StartPlanDateTime | DATETIME | |

| EndActivityDateTime | Date/Time End Activity | CYY.CYY_DTEDAT / CYY.CYY_HREDAT | DATETIME | TBLInWODet.EndPlanDateTime | DATETIME | |

| ApprovedQuantity | Approved Quantity | CYY.CYY_QTATAP | DEC(13,4) | |||

| ScrapQuantity | Scrapped Quantity | CYY.CYY_QTATRF | DEC(13,4) | |||

| MachineCode | Code Machine | CYY.CYY_CDMQ | CHAR(20) | TBLInWODet.ResourceCode | CHAR(15) | |

| MachineDescription | Description of Machine | CYY.CYY_DSMQ | CHAR(40) | |||

| ActivityQuantity | Estimated Quantity | CYY.CYY_QTAT | DEC(12,4) | TBLInWODet.QTY | DEC(19,4) | |

| StandardSetup | Standard Time Preparation | CYY.CYY_QTPASU | NUM(10) | |||

| StandardActivity | Standard Time Operation | CYY.CYY_QTPAAT | NUM(10) | |||

| StandardPostprocessing | Standard Time Post_process | CYY.CYY_QTPAPP | NUM(10) | |||

| StandardMachine | Standard Time Machine | CYY.CYY_QTPAMQ | NUM(10) | |||

| StandardOperator | Standard Time MOD | CYY.CYY_QTPAOE | NUM(10) | |||

| UsedCapacity | Capacity Used | CYY.CYY_QTVMAT | DEC(12,4) | |||

| ActivityTimeQuantity | Activity Available Time | CYY.CYY_HRDI | CHAR(08) | |||

| ReportQuantity | Reported Quantity | CYY.CYY_QTATRP | DEC(13,4) | |||

| ReworkQuantity | Reworked Quantity | CYY.CYY_QTATRT | DEC(12,4) | |||

| StartSetupDateTime | Date/Time Start Setup | CYY.CYY_DTBGSU / CYY.CYY_HRBGSU | DATETIME | |||

| EndSetupDateTime | Date/Time End Setup | CYY.CYY_DTEDSU / CYY.CYY_HREDSU | DATETIME | |||

| TimeSetup | Time Setup | CY9.CY9_QTTESU | NUM(10) | TBLInWODet.SetUpTime | TINYINT | |

| TimeMachine | Machine Time | CY9.CY9_QTTEMQ | NUM(10) | TBLInWODet.StdSpeed | DEC(28,23) | |

| TimeOperator | Time MOD | CY9.CY9_QTTERC | NUM(10) | |||

| TimePostprocessing | Post Process Time | CY9.CY9_QTTEPP | NUM(10) | |||

| QuotaActivityID | ID Split | CYY.CYY_IDATQO | CHAR(05) | ActivityCode+ TBLInWODet.WODetCode | CHAR(10) | |

| WorkCenterCode | Work Center | CY9.CY9_CDCETR | CHAR(10) | TBLInWODet.ManagerGrpCode | CHAR(15) | |

| ReportedSplit | Reported Split | CYY.CYY_LGQORP | BOOELAN | |||

| StatusActivityType | State Operation | CYY.CYY_TPSTAT | CHAR(01) | |||

| ToolCode | Tool | CYY.CYY_CDFE | CHAR(20) | |||

| ToolQuantity | Quantity Tool | CYY.CYY_QTFE | NUM(03) |

Note:

- The tags not used by PCP Protheus x PC-Factory integration, even in messages, described in Schema of TOTVS Single Message are not mentioned in this document.

- The tag Type (Order Type) is generated with value "1" - Internal Order.

- The tag RequestType (Request Type) identifies if the request can be done separately from the production report, according to rule below:

If parameter MV_REQAUT has 'D' the DIRECT materials are entered and the INDIRECT are automatically loaded;

If parameter MV_REQAUT has 'A' the consumption of materials is executed in all components;

This tag has the following values: 1-Direct, 2-Indirect. - The tag Allocation Type (Allocation Type) is generated with value "3" - Absolute Order.

- The session ListOfAllocatedMaterial follows some rules for allocation:

If item controls address and did not generate SBC it does not generate data from list ListOfAllocatedMaterial (verificar only when parameter MV_LOCALIZ = S);

If item controls trace and did not generate the batch in SD4, it does not generate data from list ListOfAllocatedMaterial;

If item does not control address or batch, it must generate data from list ListOfAllocatedMaterial based on SD4. - The tags of operations os session order ListOfActivityOrders can have different origin according to parameterization or executed routines. If you execute the machine MATA690, table SH8 is used. When parameter MV_PCPATOR has 'S', table SHY is used. If parameter MV_PCPATOR has 'N', table SG2 is used.

- The tag Split of session ListOfActivityOrders is generated when there is unfolding of operation in several resources. Generated when using Shop Floor.

- The tag ActivityType (Operation Type) is generated with value '1' - Register;

- The tag UnitTimeType (Unit Measure Type) is generated with value '1' - Time;

- The tag UnitItemNumber is used to register the standard batch of operation production.

- For PC-Factory, indicate in which operation the component is consumed. When component x operation concept is not used, link components in last operation.

- The tag TimeMachine (Machine Time) indicates time for production order.

By using parameter MV_PCPATOR the time is SHY.HY_TEMPOM.

When machine load is used, use the difference between SH8.H8_HRINI and SH8.H8_HRFIM.

The time can have variation according to Operation Type (when it is not in SHY):

Operation Type 1 Regular: Apply the batch time the quantity of order. Which are: (SG2.G2_TEMPAD / SG2.G2_LOTEPAD) * SC2.C2_QUANT) / SH1.H1_MAOOBRA. Note: If time and lot are zero, consider 1.

Operation Type 2 Fixed and 3 Unlimited: Regardless of amount, the time is the same. Which are: SG2.G2_TEMPAD. Note: If zero delivers 1.

Operation Type 4 Minimum Time: Considers the multiple quantity of batch. Example: Lot = 10. Time = 5. Order Amt. = 7. It must consider time to make 10 spare parts. The same calculation is type 1 Regular.

Another point to consider is the PC-Factory waits time in Centesimal. When parameter MV_TPHR is other than 'C', time is converted to centesimal. - The tag TimeResource (Resource Time) indicates tiem to make standard batch.

- The tag LaborCode (Labor Code) is indicated by 'MOD' + Cost Center.

- The session ListOfQuotaActivity is generated only when Shop Floor is active.

- The tag StatusActivityType has the following values: 1=Not Started;2=Programmed;3=Released;4=Started;5=Finished;6=Suspended

- The co-product is sent to PC-Factory na ListOfMaterialOrders, tag MaterialQuantity, e na ListOfAllocatedMaterial, tag AllocationQuantity (quando existir) com quantidade negativa. O PC-Factory deverá enviar ao Protheus na mensagem de apontamento ProductionAppointment na SupplyOrder the tag UsedQuantity with negative quantity, then the ERP understands that it is the input of a co-product in stock. The type of transaction for co-product, it is registered in the PCPA109 and must have content lower than 500, as it is an input and must be type RETURN and the field Update Allocation must be yes (routine MATA230).

- A tag TimeIndMES deve ser gerada como '3'.

Processes

Production Annotation Transaction: ProductionAppointment_2_000.xsd

Message Identifier: ProductionAppointment

Version: 2_003

Protheus Module: SIGAPCP/SIGASFC

Sending Type: Synchronous

Note:

This message is generated by PC-Factory and sent to Protheus.

| Message | Tag | Description | Table/Field Protheus PCP | Table Field Protheus SFC | Type | Table/Field: PC-Factory | Tipo |

|---|---|---|---|---|---|---|---|

| BusinessContentType | MachineCode | Machine | SH6.H6_RESOURCE | CYV.CYV_CDMQ | CHAR(06) | TBLOutInteg.ResourceCode | CHAR(15) |

| ProductionOrderNumber | Production Order | SH6.H6_OP | CYV.CYV_NRORPO | CHAR(20) | TBLOutInteg.WOCode | CHAR(41) | |

| ActivityCode | Operation | SH6.H6_OPERAC | CYV.CYV_CDAT | CHAR(02) | TBLOutInteg.WODetCode | CHAR(10) | |

| Split | Split | SH6.H6_DESDOBR | CYV.CYV_IDATQO | CHAR(04) | TBLOutInteg.WODetCode | CHAR(10) | |

| ActivityID | ID Operation | -- | -- | ||||

| ItemCode | Product | SH6.H6_PRODUCT | CYV.CYV_CDACRP | CHAR(15) | TBLOutInteg.ProductCode | CHAR(20) | |

| ApprovedQuantity | Approved Quantity | SH6.H6_QTDPROD | CYV.CYV_QTATAP | DEC(11,2) | TBLOutInteg.Qty | DEC(19,4) | |

| ScrapQuantity | Scrapped Quantity | SH6.H6_QTDPERD | CYV.CYV_QTATRF | DEC(11,2) | TBLOutInteg.Qty | DEC(19,4) | |

| ReworkQuantity | Reworked Quantity | -- | -- | ||||

| StartSetupDateTime | Date/Time Start Setup | -- | CYV_DTBGSU CYV_HRBGSU | DATETIME | |||

| EndSetupDateTime | Date/Time End Setup | -- | CYV_DTEDSU CYV_HREDSU | DATETIME | |||

| SetupCode | Setup Code | -- | CYV_CDSU | CHAR(10) | |||

| OpTimeInt | Operation Time | -- | CYV.CYV_QTTERP | NUM(10) | |||

| ProductionShiftCode | Code Shift Model | -- | CYV.CYV_CDTN | CHAR(08) | |||

| ProductionShiftNumber | Shift Number | -- | CYV.CYV_NRTN | CHAR(05) | TBLOutInteg.Shift | SMALLINT | |

| DocumentCode | Document | -- | CYV.CYV_NRDO | CHAR(20) | TBLOutInteg.DocNumber | CHAR(20) | |

| DocumentSeries | Series Document | -- | CYV.CYV_NRSR | CHAR(05) | |||

| StartReportDateTime | Date/Time Start Report | SH6.H6_DATAINI SH6.H6_HORAINI | CYV.CYV_DTRPBG CYV.CYV_HRRPBG | DATETIME | TBLMSGERP.Start | DATETIME | |

| EndReportDateTime | Date/Time End Report | SH6.H6_DATAFIN SH6.H6_HORAFIN | CYV.CYV_DTRPED CYV.CYV_HRRPED | DATETIME | TBLMSGERP.End | DATETIME | |

| ReversedReport | Annotation Reversal | TRUE or FALSE | TRUE ou FALSE | BOOLEAN | |||

| ReversalDate | Reversal Date | -- | CYV.CYV_DTEO | DATE | TBLOutInteg.DTEv | DATETIME | |

| ReportDateTime | Date/Time Report | SH6.H6_DTAPONT | CYV.CYV_DTRP CYV.CYV_HRRP | DATETIME | TBLOutInteg.DtEv | DATETIME | |

| WarehouseCode | Deposit | SH6.H6_LOCAL | CYV.CYV_CDDP | CHAR(02) | TBLOutInteg.WarehouseCode | CHAR(15) | |

| LotCode | Lot/Series | SH6.H6_LOTECTL | CYV.CYV_CDLOSR | CHAR(10) | TBLOutInteg.LotCode | CHAR(41) | |

| LotDueDate | Date Validity Lot | SH6.H6_DTVALID | CYV.CYV_DTVDLO | DATE | TBLLot.DtValidity | DATETIME | |

| CloseOperation | Close Operation | SH6.H6_PT | CYV.CYV_LGEDRP | BOOLEAN | |||

| LocationCode | Location | -- | CYV.CYV_CDLC | CHAR(20) | TBLOutInteg.Address1Code | CHAR(15) | |

| ListOfReversalAppointments | |||||||

| IntegrationReport | Record to be reversed | CHAR(10) | TBLOutInteg.TransacType | TINYINT | |||

| ReversalType | Type of Reversal | CHAR(01) | |||||

| ReversalQuantity | Quantity reverted | -- | DEC(18,4) | ||||

| WasteAppointment | |||||||

| WasteCode | Code Scrap | SBC.BC_REASON | CY0.CY0_CDRF | CHAR(02) | TBLOutInteg.ScrapCode | CHAR(15) | |

| WasteDescription | Description Scrap | SBC.BC_DESCRI | CY0.CY0_DSRF | CHAR(40) | |||

| ScrapQuantity | Scrapped Quantity | SBC.BC_QUANT | CY0.CY0_QTRF | DEC(11,2) | TBLOutInteg.Qty | DEC(18,4) | |

| ScrapProduct | Scrapped Product | SBC.BC_PRODUCT | -- | CHAR(15) | |||

| WareHouseCode | Deposit Scrapped Product | SBC.BC_LOCORIG | -- | CHAR(10) | |||

| ScrapProductTo | Generated Scrap | SBC.BC_CODDEST | -- | CHAR(15) | |||

| WareHouseCodeTo | Deposit of generated scrap | SBC.BC_LOCAL | -- | CHAR(10) | |||

| AdressCode | Origin Address | SBC.BC_LOCALIZ | CHAR(15) | ||||

| AdressCodeTo | Destination Address | SBC.BC_LOCDEST | CHAR(15) | ||||

| NumberSeries | Number of Series | SBC.BC_NUMSERI | CHAR(20) | ||||

| NumberSeriesTo | Number of Series Destination | SBC.BC_NSEDEST | CHAR(20) | ||||

| LotCode | Lot | SBC.BC_LOTECTL | CHAR(10) | ||||

| SubLoteCode | Sub Lot | SBC.BC_NUMLOTE | CHAR(06) | ||||

| LotDueDate | Validity Date | SBC.BC_DTVALID | DATE | ||||

| CostCenterCode | Cost Center | SBC.BC_CC | CHAR(09) | ||||

| ResourceAppointment | |||||||

| OperatorCode | Operator Code | -- | CYW.CYW_CDOE | CHAR(20) | TBLOutInteg.UserCode | CHAR(30) | |

| StartDateTime | Start Date/Time | -- | CYW.CYW_DTBGRP CYW.CYW_HRBGRP | DATETIME | TBLMSGERP.Start | DATETIME | |

| EndDateTime | End Date/Time | -- | CYW.CYW_DTEDRP CYW.CYW_HREDRP | DATETIME | TBLMSGERP.End | DATETIME | |

| MOBTime | Time Direct Labor | -- | CYW.CYW_QTTEOE | NUM(10) | |||

| ExtraTime | Extra Time | -- | CYW.CYW_QTTEEX | NUM(10) | |||

| UtilTime | Useful Time | -- | CYW.CYW_QTTEUT | NUM(10) | |||

| ProductionShiftCode | Code Shift Model | -- | CYW.CYW_CDTN | CHAR(08) | |||

| ProductionShiftNumber | Number Shift | -- | CYW.CYW_NRTN | CHAR(05) | TBLOutInteg.Shift | SMALLINT | |

| SupplyOrder | |||||||

| ProductionOrderNumber | Number Production Order | SD3.D3_OP | CZP.CZP_NRORPO | CHAR(20) | TBLOutInteg.WOCode | CHAR(41) | |

| MaterialCode | Code Reservation Item | SD3.D3_COD | CZP.CZP_CDMT | CHAR(15) | TBLOutInteg.ProductCode | CHAR(20) | |

| UsedQuantity | Quantity Used | SD3.D3_QUANT | CZP.CZP_QTRPPO | DEC(12,2) | TBLOutInteg.Qty | DEC(19,4) | |

| WarehouseCode | Code Deposit | SD3.D3_LOCAL | CZP.CZP_CDDP | CHAR(02) | TBLOutInteg.WarehouseCode | CHAR(15) | |

| LocationCode | Location | SD3.D3_LOCALIZ | CZP.CZP_CDLC | CHAR(15) | TBLOutInteg.Address1Code | CHAR(15) | |

| LotCode | Lot/Series | SD3.D3_LOTECTL ou SD3.D3_NUMSERI | CZP.CZP_CDLO | CHAR(20) | TBLOutInteg.LotCode | CHAR(41) | |

| ActivityCode | Code Operation | -- | CZP.CZP_CDAT | CHAR(02) | TBLOutInteg.WODetCode | CHAR(10) | |

| ScriptCode | Script | -- | CZP.CZP_CDRT | CHAR(02) | |||

| ReportToolActivity | |||||||

| ToolCode | Code Tool | -- | CZ0.CZ0_IDFE | CHAR(20) |

Note:

- The default annotation for this integration is MATA681.

- The fields Machine, Production Order, Operation, Product and Date/Time Report are mandatory.